Introduction

Manufacturing is the backbone of many industries, and optimizing its processes and operations is essential for staying competitive in today’s dynamic market. In this article, we will delve into practical approaches to enhance efficiency, quality, and overall productivity in your manufacturing endeavors.

- Cultivate a Culture of Continuous Improvement

To set the foundation for manufacturing success, foster a culture of continuous improvement within your organization. Encourage all employees, from the shop floor to management, to contribute their ideas and suggestions for process optimization and product innovation. Regularly hold meetings and workshops to review progress, identify bottlenecks, and celebrate successful improvements.

- Embrace Lean Manufacturing Principles

Lean manufacturing is a time-tested methodology that eliminates waste, enhances efficiency, and drives value. Implement lean principles, such as 5S (Sort, Set in order, Shine, Standardize, Sustain), Kanban, and Just-In-Time (JIT) production, to streamline workflows and reduce unnecessary inventory. By doing so, you can improve production speed, cut costs, and respond to customer demands more effectively.

- Invest in Workforce Development

Your workforce is the heart of your manufacturing success. Invest in training and development programs to empower your employees with the skills and knowledge they need to excel. Provide opportunities for cross-training, upskilling, and professional growth to boost employee engagement and loyalty. A well-trained workforce leads to improved product quality and operational efficiency.

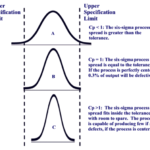

- Prioritize Quality Control and Assurance

Maintaining exceptional product quality is non-negotiable for manufacturing success. Implement stringent quality control and assurance processes at each stage of production. Regularly inspect raw materials, monitor in-process quality, and conduct final product inspections. By catching and rectifying defects early, you can avoid costly recalls and rework, and ensure customer satisfaction.

- Leverage Technology and Industry 4.0

To stay competitive, manufacturers must embrace technological advancements. Adopt Industry 4.0 technologies like the Internet of Things (IoT), Artificial Intelligence (AI), and Big Data analytics to collect and analyze valuable data in real-time. This data-driven approach enables predictive maintenance, optimized production schedules, and enhanced decision-making.

- Optimize Supply Chain Collaboration

A smooth and efficient supply chain is essential for manufacturing success. Establish strong partnerships with suppliers and customers, promoting open communication and collaboration. Work together to forecast demand accurately, negotiate favorable contracts, and ensure timely deliveries. A well-optimized supply chain enhances overall efficiency and reduces the risk of disruptions.

- Implement Risk Management Strategies

Manufacturing is not without its risks, whether it’s machine breakdowns, supply chain disruptions, or market fluctuations. Develop comprehensive risk management strategies to identify potential threats and mitigate their impact. Creating contingency plans, ensuring equipment redundancy, and diversifying suppliers can safeguard your manufacturing operations.

- Embrace Sustainable Manufacturing Practices

Incorporate sustainability into your manufacturing processes to align with environmentally conscious consumer demands and reduce your ecological footprint. Introduce waste reduction measures, recycle materials, and consider environmentally friendly alternatives in your production. Sustainable practices not only protect the environment but also enhance your brand reputation.

Conclusion

Achieving manufacturing success requires dedication, innovation, and a commitment to continuous improvement. By fostering a culture of innovation, embracing lean principles, investing in workforce development, prioritizing quality control, and leveraging technology, you can streamline operations and excel in a competitive market. Moreover, optimizing supply chain collaboration, implementing risk management strategies, and adopting sustainable practices will position your organization for long-term success. Stay proactive, open to change, and always seek new ways to improve, and your manufacturing journey will be one of excellence and growth.