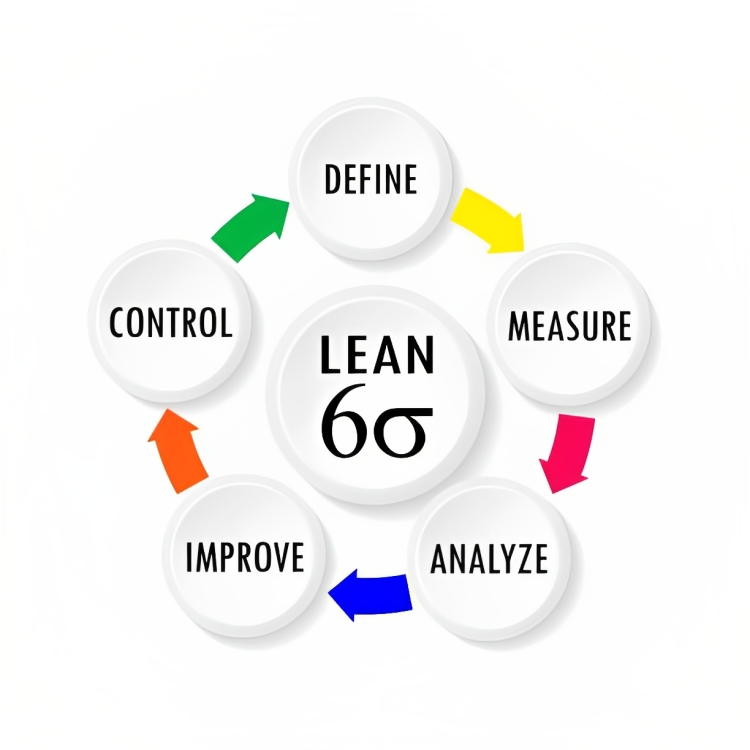

Streamline synergy presents Pro-Lean Six Sigma

Courses are aligned with international standards and best practices. You will learn the essential tools and techniques to identify and eliminate problems, streamline and optimize processes, and deliver value to your customers.

Our membership program is designed to provide maximum flexibility for individuals and organizations looking to improve their processes and drive business performance. You can take as many courses as you need, at your own pace, and on your own schedule.

Additionally, our membership program includes access to our team of experts who can provide guidance and support as you work to implement process improvements in your organization.

We are committed to helping our members succeed and achieve their goals through continuous learning and improvement.

Introducing our revolutionary Lean Six Sigma training program, designed to break away from traditional approaches and provide a comprehensive learning experience. Unlike courses that run for a mere 5 days, we understand that true mastery of Lean Six Sigma requires more time and dedication.

That’s why we offer a lifetime price guarantee, ensuring that the cost of your training will never change. With our program, you have the freedom to train as many people as you want, allowing your entire team to benefit from this valuable knowledge. Additionally, we provide the option to refresh your training, giving you complete control over your learning journey.

Our approach is to combine my knowledge of the industry with a customer-focused and results-driven attitude. I strive to understand customer needs and develop solutions that help them achieve their goals while meeting their budget requirements. My focus is on creating value for the customer through process efficiency, cost reduction and quality improvement initiatives.

Get a Free Quote

Thank you for your interest in Streamlinesynergy presents

Proleansixsigma’s services. We would be happy to provide you with a free quote for our Six Sigma training or consulting services.